SF-Zero

SF-Zero: Zero defect, efficient toxic vapour monitoring and control solution for process manufacturers

SF-Zero will develop and demonstrate a Zero defect, efficient toxic vapour monitoring and control solution for process manufacturers, such as chemical industries (e.g., perfume & fragrance manufacturing), able to:

1) Reduce errors: SF-Zero will increase the accuracy and understanding of the weighing and mixing processes, since recorded measurements and analysis of historical data will allow to identify defects and anomalies causes.

2) Provide digital services for live monitoring and alerting for errors and safety issues: SF-Zero’s IoT capabilities will detect potential errors in weighing, vapours generation and exposures and will provide a supervision platform and generate alerts accordingly.

3) Integration with other IoT sensors and capabilities: air quality sensors and cloud connection are just the starting point for a future interconnected fume hoods’ system. Simple integration with other sensors, software tools and services in the cosmetics industry, will boost the adoption of Industry4.0 in this sector.

Such features will successfully support operators to complete complex processes while identifying anomalous situations, and promptly react to avoid product defects and more severe safety risks. SF-Zero is the evolution of the existing ‘smart-Flow’ product, a new generation fume hood, designed and manufactured by Osmose and already distributed in 13 countries worldwide.

Indeed, SF-Zero is the natural next-generation of the currently commercialized smart-Flow product that Osmose will develop together with R2M, thanks to its technical expertise in digitalisation and AI for anomalies detection, and sector knowledge of the zero-defect for manufacturing. The new product will provide new, most demanded, and expected capabilities, like digital dashboards, voice control, storage and analysis of real time and historical information in a fast and efficient manner, allowing engineers and operators to react to different situations and promptly support them in taking strategic and informed decisions.

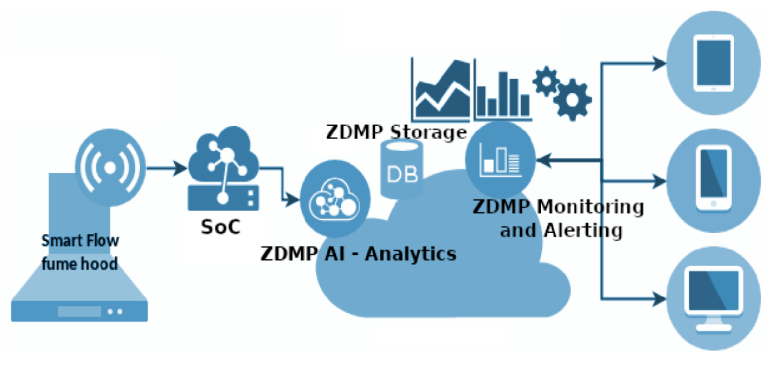

The project SF-Zero will offer the opportunity to leverage on the current, significative ZDMP expertise, technical offer, and network to extend the digitalisation of the SF-Zero solution.

ZDMP aims at providing an extendable platform for supporting factories with a high interoperability level to cope with the concept of connected factories to reach the zero defects goal. In this context, ZDMP will allow end-users to connect their systems (i.e. shopfloor and ERP Systems) to benefit from the features of the platform. These benefits include products and production quality assurance among others.

Please visit ZDMP Website – ZDMP LinkedIn – ZDMP Twitter for more info!

This project has received funding from the European Union’s Horizon 2020 research and innovation programme through the ZDMP project with grant agreement No 825631

For any information you might need. We will assist you throughout the process.